What is +Cope?

+Cope represents Borematic’s supportive inspection services aimed at meeting additional customer requirements. While Borematic primarily specializes in video endoscope and borescope inspection services, +Cope goes beyond these core offerings to provide supplementary assistance tailored to the unique needs of our clients.

+Cope

Why does Borematic provide +Cope services despite specializing in video endoscope and borescope inspections?

At Borematic, we understand that our clients may have diverse and evolving needs beyond the scope of traditional inspection services. Therefore, we offer +Cope services to ensure that we can effectively address any additional requirements our clients may have. +Cope services have evolved over time in response to customers’ requests for supportive inspection services, such as dimensional, visual, and functional inspections. Whether it’s providing extra documentation, conducting specialized tests, or offering personalized attention, +Cope allows us to go the extra mile in delivering comprehensive solutions that exceed our clients’ expectations.

+Cope Services:

- Dimensional Inspection: We provide precise dimensional inspection services to ensure that your products meet the required specifications and standards.

- Visual Inspection: Our visual inspection services are designed to detect surface defects, irregularities, and anomalies with meticulous attention to detail.

- Functional Inspection: Borematic conducts functional inspections to evaluate the performance and functionality of your equipment or products, ensuring optimal functionality.

- First Article or PPAP Inspection: Trust Borematic for thorough first article and PPAP inspections to verify that your products meet the necessary requirements before mass production.

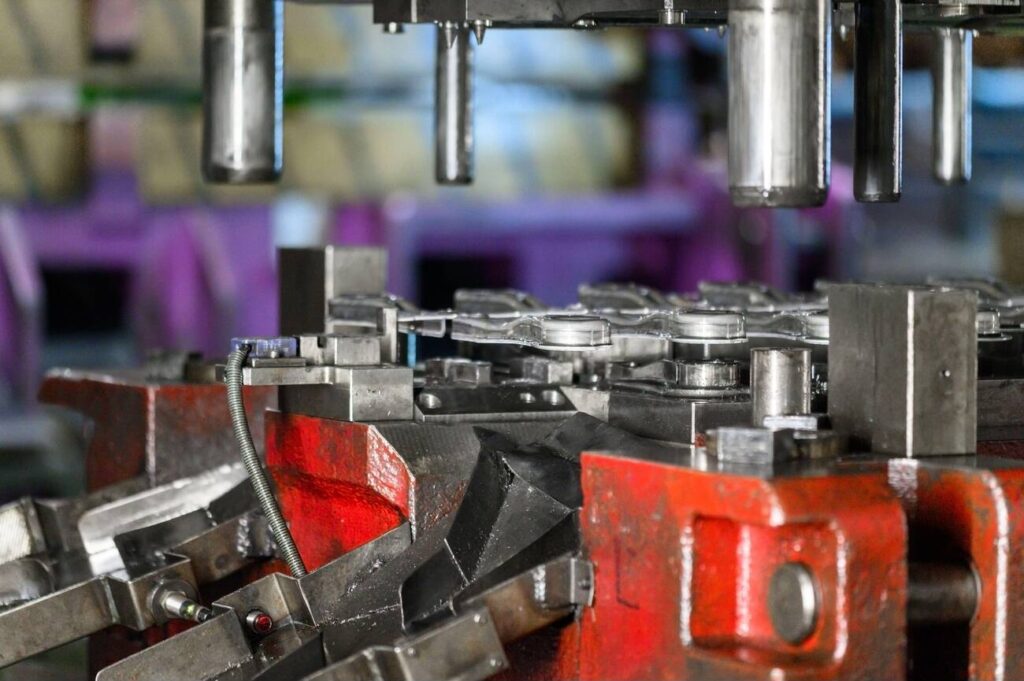

- Machinery Inspection: We offer comprehensive machinery inspection services to assess the condition, performance, and safety of industrial machinery.

- Preshipment Inspection: Our preshipment inspection services help identify any discrepancies or defects in products before they are shipped, ensuring customer satisfaction and compliance with quality standards.

- Supplier Quality Engineering and Supplier Development Engineering: Borematic provides expert quality engineering services to assist you in optimizing processes, improving product quality, and achieving operational excellence.

- Expediting: We recognize the importance of timely delivery and the impact it has on your project’s success. Our Expediting Inspection Service is designed to support your project management needs and ensure that your goods are delivered on time and to the highest quality standards.

+COPE IN TURKIYE

Inspection, Quality Control, Expediting, Audit, Supplier Development and Supplier Quality Engineering Services In TURKEY

Why Choose Borematic +Cope Services?

- Commitment to Quality: We are committed to delivering inspection services of the highest quality, ensuring customer satisfaction and compliance with industry standards.

- Experienced Professionals: Our team consists of experienced professionals with expertise in various inspection techniques and methodologies.

- Advanced Technology: Borematic utilizes cutting-edge technology and equipment to conduct inspections with precision and efficiency.

- Tailored Solutions: We understand that every project is unique, and we offer customized inspection solutions to meet your specific requirements.

- Timely Delivery: We prioritize timely delivery without compromising on the quality of our services, ensuring minimal disruption to your operations.

Contact Us Today

Experience the difference with Borematic’s superior inspection services. Contact us today to discuss your inspection needs and discover how we can help ensure the quality and integrity of your products and processes.

INDUSTRIES SERVED:

Automotive: From precision components to complex systems, we support the automotive industry with comprehensive inspection solutions.

Machinery: Our services cater to the machinery sector, ensuring optimal performance and safety across various equipment types.

Energy: Whether conventional or renewable, we provide inspection services to the energy industry to uphold operational efficiency and reliability.

Oil & Gas: Our expertise in inspection helps maintain the integrity and safety of oil, gas, and petroleum infrastructure.

Renewable Energy: We support the renewable energy sector with inspection services tailored to wind, solar, and other sustainable energy technologies.

HVAC: Our inspections ensure the quality and performance of heating, ventilation, and air conditioning systems.

Aviation: With stringent quality standards, our inspection services contribute to the safety and reliability of aviation components and systems.

Defense: We provide inspection services to the defense industry, ensuring compliance with rigorous standards and specifications.

Trucks: Our inspections cover a wide range of truck components and systems, ensuring reliability and safety on the road.

Construction Machinery: We support the construction industry with inspections to maintain the performance and durability of machinery and equipment.

Agricultural Machinery: Our services help ensure the efficiency and reliability of agricultural machinery, supporting productivity in farming operations.

General Machinery: From industrial equipment to consumer goods, we provide inspection solutions for a variety of general machinery applications.

Petrochemicals: Our inspections contribute to the safety and reliability of petrochemical facilities and equipment.

Railway: We support the railway industry with inspections to ensure the safety and efficiency of rail infrastructure and rolling stock.

+COPE IN TURKIYE

Inspection, Quality Control, Expediting, Audit, Supplier Development and Supplier Quality Engineering Services In TURKEY

MANUFACTURING PROCESSES:

Investment Casting: We offer inspection services for investment casting processes, ensuring the quality and integrity of cast components.

Sand Casting: Our inspections cover sand casting processes to verify the quality and dimensional accuracy of cast parts.

Die Casting: We provide inspection solutions for die-casting processes, ensuring the reliability of cast components for various applications.

Centrifugal Casting: Our inspections help maintain the quality and performance of centrifugal cast components.

CNC Machining: We offer inspection services for CNC machining processes, ensuring the precision and accuracy of machined parts.

Plastic Injection Molding: Our inspections cover plastic injection molding processes, ensuring the quality and consistency of molded components.

Heat Treatment: We provide inspection solutions for heat treatment processes, ensuring the desired mechanical properties of heat-treated parts.

Plating: Our inspections verify the quality and thickness of plating coatings, ensuring corrosion resistance and aesthetic appeal.

Sheet Metal Processing: We offer inspection services for sheet metal processing, ensuring the dimensional accuracy and quality of fabricated parts.

Stamping, Punching, Press Bending: Our inspections cover various metal forming processes, ensuring the integrity and accuracy of formed parts.

Laser Cutting: We provide inspection solutions for laser cutting processes, ensuring precise cutting and dimensional accuracy.

Welding: Our inspections verify the quality and integrity of welded joints, ensuring structural strength and reliability.

At Borematic, we combine our technical expertise, advanced technology, and commitment to quality to deliver inspection services that meet the highest standards. Contact us today to discuss your inspection needs and discover how we can support your success.