Welcome to Borematic’s Dimensional Inspection Services!

Borematic, situated in Turkey, is your premier destination for meticulous dimensional inspection services tailored to meet your exacting standards. We employ a range of cutting-edge techniques and equipment to ensure that your products adhere to the highest specifications and industry standards.

Types of Dimensional Inspections:

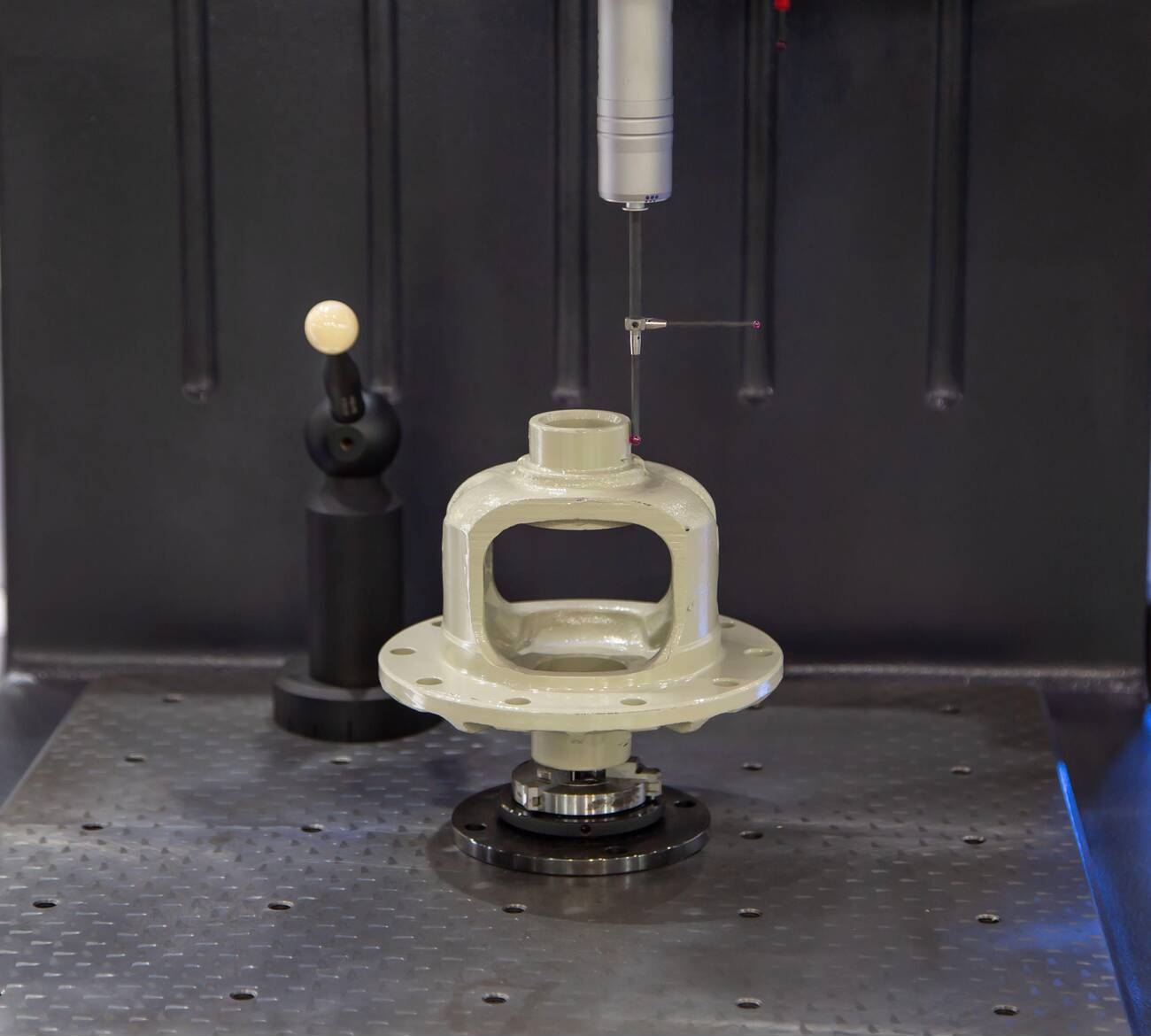

- Coordinate Measuring Machine (CMM) Inspection: Our advanced CMM inspection services utilize state-of-the-art machinery to precisely measure the geometrical characteristics of your components. With high accuracy and repeatability, we ensure that your products meet the most stringent dimensional requirements.

- Caliper Inspection: Utilizing precision calipers, our expert inspectors meticulously assess dimensional features such as length, width, and thickness. Whether it’s a simple or complex geometry, our caliper inspections guarantee meticulous measurement accuracy.

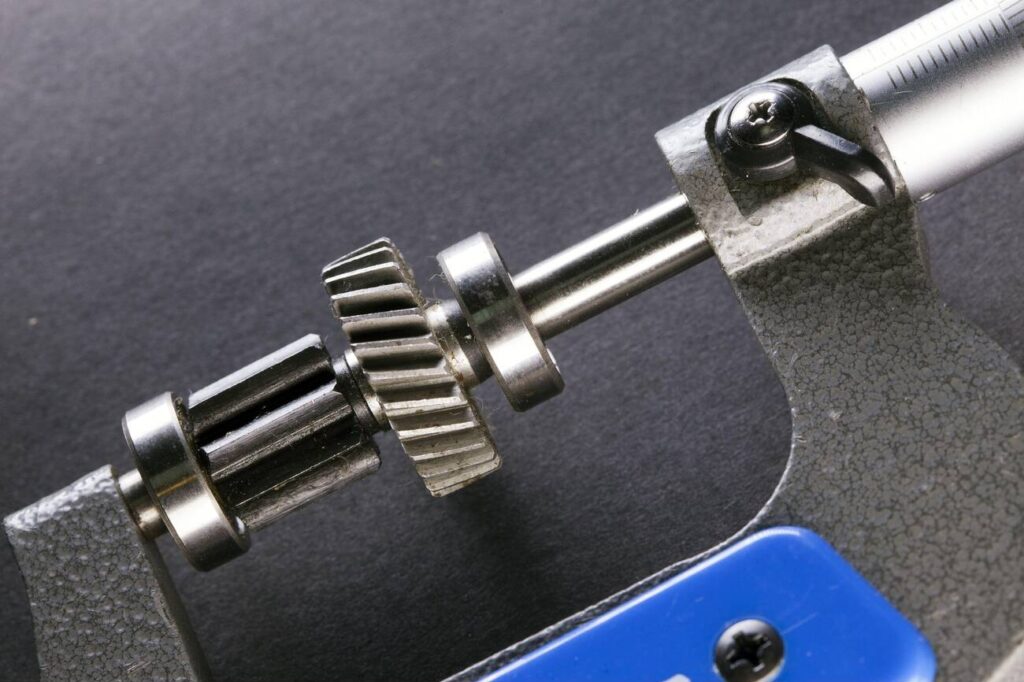

- Micrometer Inspection: With micrometer inspections, we delve into fine measurements, ensuring accuracy down to the micrometer level. From diameters to depths, our micrometer inspections provide detailed insights into critical dimensional features.

- Thread Go-No-Go Gauge Inspection: Threads play a crucial role in many components, and our thread go-no-go gauge inspections ensure that the threading meets specified tolerances. We meticulously assess thread pitch, depth, and diameter to guarantee optimal performance and compatibility.

- Plug Go-No-Go Gauge Inspection: Our plug go-no-go gauge inspections focus on internal diameters and bores. By utilizing precision gauges, we verify that the internal dimensions of your components conform to required specifications, ensuring proper fit and functionality.

- Height Gauge Inspection: Height gauge inspections enable us to accurately measure vertical dimensions and features such as heights, steps, and depths. With our height gauge capabilities, we ensure consistency and precision in dimensional attributes across your products.

- Dial Gauge Measurement: Dial gauges are utilized for precise measurements of linear dimensions, deviations, and alignments. With dial gauge measurements, we ensure accurate and reliable assessment of critical dimensional parameters, enhancing the quality and performance of your products.

Services Offered:

- Comprehensive Dimensional Analysis: Our expert team conducts thorough dimensional analyses using a combination of advanced equipment and techniques, ensuring that every aspect of your components meets specified requirements.

- Customized Inspection Plans: We understand that each project is unique, which is why we offer tailored inspection plans to address your specific needs and challenges. Our flexible approach ensures that you receive personalized service that aligns perfectly with your objectives.

- Detailed Reporting: Our comprehensive inspection reports provide clear and concise documentation of dimensional measurements and characteristics. With detailed insights at your fingertips, you can make informed decisions and drive continuous improvement initiatives.

Trust Borematic to be your partner in precision, reliability, and quality assurance. Contact us today to discover how our dimensional inspection services can elevate the quality of your products and drive your success!

Industries:

Borematic serves a diverse range of industries with our precision dimensional inspection services. Whether you’re in the automotive sector, requiring precise measurements for components vital to vehicle performance, or in the aerospace and defense industries, where stringent quality standards are non-negotiable, we’ve got you covered. Our expertise extends to the machinery and manufacturing sectors, encompassing a wide array of processes such as sand casting, investment casting, die casting, CNC machining, stamping, forging, plastics injection molding, press forming, laser and plasma cutting, and press bending. We understand the unique challenges faced by each industry and tailor our inspection solutions to ensure optimal performance and reliability. Additionally, our services cater to the HVAC, energy, oil and gas, construction machinery, truck, and agriculture machinery sectors, where precision measurements are critical for safety, efficiency, and compliance. Trust Borematic to be your partner in quality assurance, no matter the industry. Contact us today to discuss how we can support your dimensional inspection needs and drive your success.