Welcome to Borematic’s Visual Inspection Services!

At Borematic, we understand the critical role that visual inspection plays in ensuring the quality and integrity of your products. With our comprehensive visual inspection services, we provide meticulous scrutiny to identify defects, anomalies, and imperfections, helping you maintain the highest standards of quality and reliability.

Types of Visual Inspections:

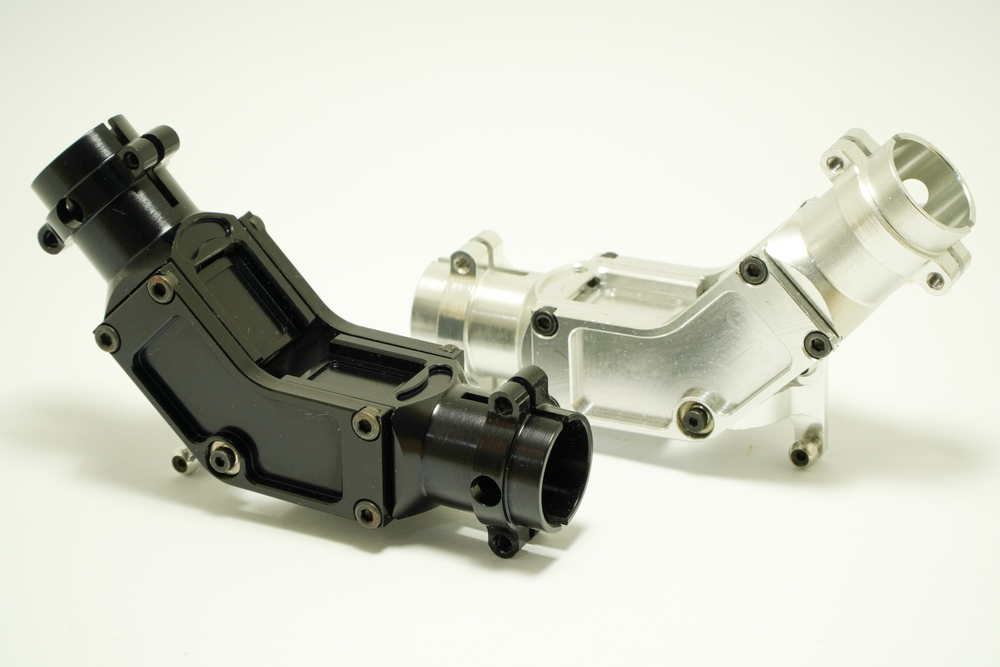

- Surface Inspection: Our expert inspectors meticulously examine the surface of your products to detect any scratches, dents, cracks, or other surface imperfections that may affect their performance or appearance.

- Weld Inspection: We specialize in weld inspection services, ensuring that weld seams meet specified standards for strength, integrity, and aesthetics. Our inspectors are trained to identify weld defects such as cracks, porosity, undercutting, and incomplete fusion, allowing for timely corrective actions.

- Dimensional Verification: In addition to visual scrutiny, we offer dimensional verification services to ensure that your products meet the required dimensional specifications and tolerances. By combining visual inspection with precise measurements, we provide comprehensive assessments of your components’ quality.

- Component Assembly Inspection: Our visual inspection services extend to component assembly, where we verify the correct assembly of parts and components, ensuring proper alignment, fit, and functionality. By identifying assembly errors early in the production process, we help you prevent costly rework and ensure product reliability.

- Surface Finish Evaluation: We assess the surface finish of your products to ensure that they meet aesthetic requirements and customer expectations. Whether it’s a smooth polished finish or a textured surface, our inspectors meticulously evaluate surface finishes to maintain consistency and quality.

- Plating/Electroplating Inspection: Borematic offers thorough inspection services for plating and electroplating processes, ensuring that coatings meet specified thicknesses and adhere properly to substrates. Our inspectors examine plating quality, adhesion, and uniformity to guarantee optimal performance and durability.

- Paint Inspection: Our paint inspection services involve assessing paint quality, coverage, adhesion, and color consistency to ensure a flawless finish and protection against corrosion and environmental factors.

Services Offered:

- Comprehensive Inspection: Our experienced team conducts thorough visual inspections using industry-leading techniques and equipment to ensure the highest level of accuracy and reliability.

- Customized Solutions: We tailor our visual inspection services to meet your specific requirements, whether you need one-time inspections or ongoing quality control support.

- Detailed Reporting: Our inspection reports provide clear documentation of inspection results, including visual observations, defect classifications, and recommended corrective actions, empowering you to make informed decisions.

Trust Borematic to be your partner in visual inspection excellence. Contact us today to learn more about how our visual inspection services can enhance the quality and reliability of your products.